Selecting the right third-party logistics (3PL) warehouse can be a game-changer for your business’s efficiency and profitability. However, understanding the true cost of 3PL fulfilment services can be complicated due to the wide variety of fees and pricing models.

One of the most frequently asked questions is: “How much does a 3PL warehouse cost?” The answer is—it varies. Costs depend on factors like order complexity, pick frequency, packaging requirements, and more. The good news? With the right details, many providers can give you a tailored quote within 24 hours.

This guide breaks down the key 3PL warehouse cost components, common pricing structures, and actionable ways to reduce your overall logistics spend.

Why Businesses Use 3PL Warehouses

3PL providers offer end-to-end logistics services for businesses of all sizes—from eCommerce startups to established retailers. These services typically include:

- Inventory storage

- Order picking and packing

- Returns management

Modern 3PLs increasingly rely on automation and AI to improve fulfilment accuracy, lower labour costs, and scale with client demand. By outsourcing logistics, businesses can focus more on growth and customer engagement.

Breakdown of 3PL Cost Components

To estimate your total fulfilment cost accurately, you need to understand each component of 3PL pricing:

1. Receiving & Inbound Handling

Fees apply when your products arrive at the warehouse and are processed into inventory. Charges vary based on:

- Whether items are palletised or loose

- The number of SKUs

- Barcode readiness

Tip: Pre-label and consolidate goods to reduce handling time and minimise costs.

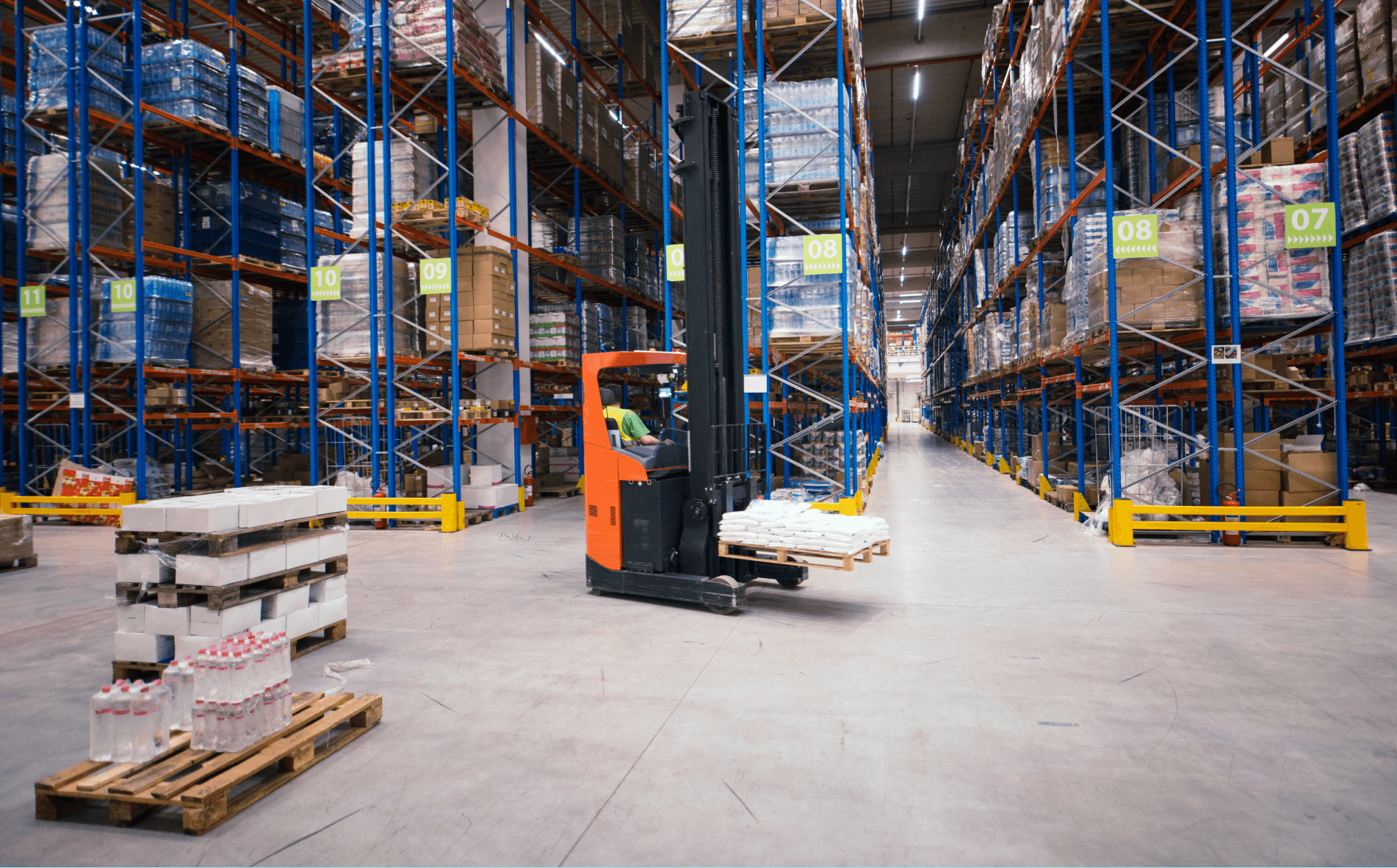

2. Storage Fees

Most warehouses charge monthly fees based on how much space your inventory occupies. Pricing usually ranges from US$15 to US$40 per pallet, with options for shelf, bin, or cubic storage.

Tip: Track inventory turnover and remove slow-moving stock to avoid unnecessary fees.

3. Pick and Pack Fees

These fees cover the labour involved in selecting and packing items for each order. Expect rates from US$0.50 to US$5 per item, depending on order size, complexity, and product type.

Tip: Project average picks per order as your product line grows to manage costs effectively.

4. Packaging Materials

You’ll be charged for packaging like boxes, satchels, or bubble wrap—typically ranging from US$0.10 to US$3 per order.

Tip: You can often supply your own packaging, but check for additional handling charges.

5. Shipping Charges

Shipping is usually the largest cost and depends on:

- Package weight (deadweight vs. dimensional)

- Destination shipping zone

Tip: Use a 3PL close to your main customer base to lower final-mile delivery expenses.

6. Labour & Admin Fees

These may appear as monthly admin fees or be embedded in other charges. They cover services like:

- Account management

- Customer support

- System integrations

Additional Costs to Watch Out For

- Onboarding & Tech Integration: One-time setup fees from US$100 to US$1,000

- Returns Handling: Fees vary based on condition checks and restocking

- Value-Added Services: Includes kitting, barcoding, and promotional inserts

- Peak Season Surcharges: Temporary increases during high-demand periods like holidays

3 Common 3PL Pricing Models

Understanding how your 3PL charges is essential for budgeting and comparison:

1. Activity-Based Pricing

You’re billed per service—storage, pick, pack, etc. Flexible and scalable for growing businesses.

2. Flat-Rate Pricing

A single fixed price per order or per month. Predictable but may include margin padding.

3. Pass-Through Pricing

You pay the exact wholesale rate plus a small markup. Offers full transparency into true costs.

Avoiding Hidden Fees

Hidden charges can erode your margins. To protect your business:

- Be Transparent: Provide detailed product data and forecasted volumes

- Vet Providers Thoroughly: Look for honest pricing practices and positive client reviews

How to Select the Right 3PL Partner

Choose a 3PL that fits your business now—and as you scale. Consider:

- Experience with your product type or order volume

- Tech capabilities and integrations

- Customer reviews (e.g., Trustpilot, Reddit)

- Service levels and responsiveness

Pro Tip: Treat your 3PL as a strategic partner. Share forecasts, marketing campaigns, and product changes to boost fulfilment accuracy and reduce delays.

Long-Term Cost Management Tips

Cost control isn’t a one-off task. Regularly review:

- Storage and shipping volumes

- Eligibility for volume discounts

- Operational performance metrics

Many savings come from collaboration, better forecasting, and regular check-ins with your 3PL provider.

Need Help Estimating 3PL Costs?

Try our free 3PL Cost Calculator or reach out to connect with pre-vetted logistics partners offering transparent, competitive pricing.